Shipping goods safely and efficiently requires the right type of packaging to ensure that products arrive in perfect condition. Whether you are a business owner shipping products to customers or an individual sending a gift to a loved one, understanding the various types of cargo packaging can help you make informed decisions. Here are the most common types of cargo packaging for perfect shipping.

1. Corrugated Boxes

Overview

Corrugated boxes are one of the most widely used types of packaging for shipping. Made from corrugated fiberboard, these boxes are strong, lightweight, and versatile. They consist of a fluted corrugated sheet sandwiched between two flat linerboards, providing durability and resistance to crushing.

Uses

Corrugated boxes are used for a variety of products, including electronics, clothing, food items, and more. Their strength makes them ideal for both single-item shipments and bulk packaging. Additionally, they are favored in e-commerce for their ability to protect goods during transit.

Benefits

- Durability: Corrugated boxes can withstand rough handling and stacking.

- Customizability: They can be customized in terms of size, shape, and printing.

- Cost-Effective: They are relatively inexpensive to produce and recycle.

2. Wooden Crates

Overview

Wooden crates are a robust and secure packaging option, particularly for heavy, fragile, or valuable items. They are made from sturdy wood panels and can be customized to fit specific product dimensions.

Uses

Wooden crates are commonly used for shipping machinery, art, antiques, and large industrial components. They provide excellent protection against impacts and environmental factors.

Benefits

- Strength: Wooden crates offer superior strength and protection.

- Customizable: They can be built to fit the exact dimensions of the product.

- Reusability: Wooden crates can be reused multiple times, making them an eco-friendly option.

3. Palletized Loads

Overview

Palletized loads involve stacking and securing goods on a pallet, typically made of wood, plastic, or metal. The pallet allows for easy handling by forklifts and pallet jacks, facilitating efficient transportation and storage.

Uses

Palletized loads are used in various industries, including retail, manufacturing, and logistics. They are ideal for shipping bulk items, large quantities of products, and heavy goods.

Benefits

- Efficiency: Pallets make it easier to move and handle large quantities of goods.

- Protection: Goods are elevated from the ground, reducing the risk of damage from moisture and dirt.

- Standardization: Pallets come in standard sizes, simplifying the shipping process.

4. Shrink Wrap and Stretch Wrap

Overview

Shrink wrap and stretch wrap are types of plastic films used to secure and protect goods during shipping. Shrink wrap is applied loosely around the item and then heated to shrink and conform tightly to the product. Stretch wrap is stretched and wrapped around items to hold them together on a pallet.

Uses

These wrapping methods are commonly used for securing boxes on pallets, bundling items together, and protecting products from dust, moisture, and tampering. They are also effective in stabilizing loads to prevent shifting during transportation.

Benefits

- Protection: Provides a barrier against dust, moisture, and damage.

- Stabilization: Helps keep items secure and in place during transit.

- Versatility: Can be used for a wide range of products and packaging configurations.

5. Foam Packaging

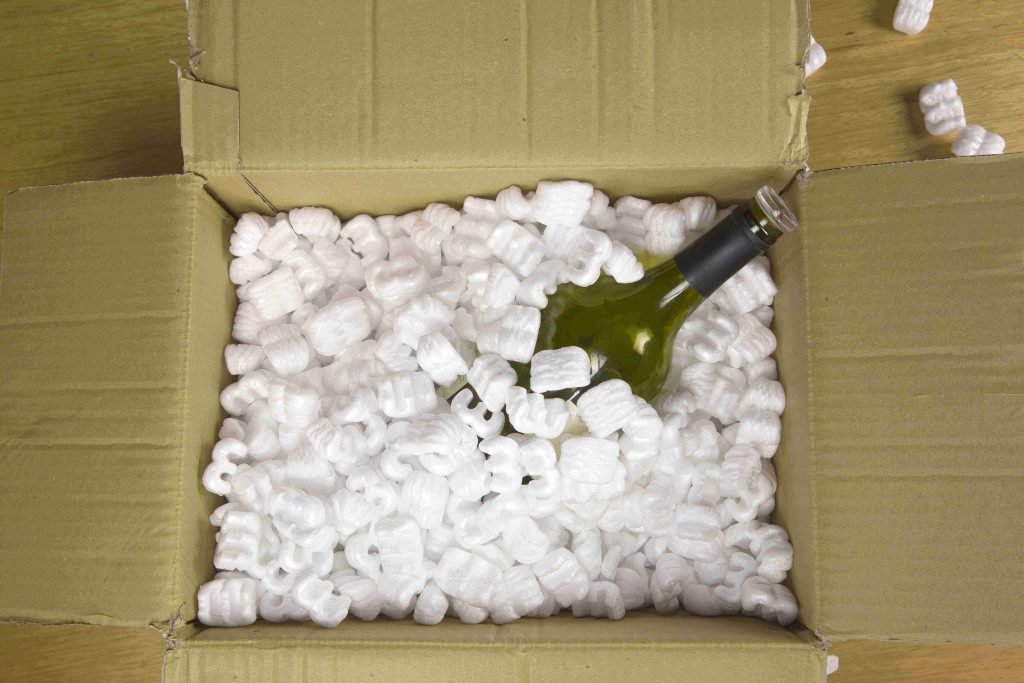

Overview

Foam packaging involves the use of various types of foam materials to protect goods during shipping. Common types include polyethylene foam, polyurethane foam, and expanded polystyrene (EPS) foam. Foam can be molded into specific shapes or used as cushioning inserts.

Uses

Foam packaging is ideal for delicate and fragile items such as electronics, glassware, and medical devices. It provides excellent shock absorption and cushioning. Additionally, it is frequently used in the aerospace and automotive industries for protecting sensitive components.

Benefits

- Shock Absorption: Protects items from impacts and vibrations.

- Lightweight: Adds minimal weight to the shipment.

- Custom Fit: Can be tailored to fit the contours of the product for maximum protection.

6. Bubble Wrap

Overview

Bubble wrap is a popular cushioning material made of plastic sheeting filled with air bubbles. It is commonly used to wrap individual items or line the inside of boxes to provide additional protection.

Uses

Bubble wrap is used for a wide variety of products, including electronics, glass items, and other fragile goods. It is often used as an extra layer of protection within other packaging. Retailers and manufacturers also rely on bubble wrap to ensure items remain secure and undamaged during shipping.

Benefits

- Cushioning: The air-filled bubbles provide excellent cushioning against impacts.

- Versatility: Can be used for wrapping, padding, and void filling.

- Reusability: Bubble wrap can be reused multiple times, making it an economical choice.

7. Air Cushions

Overview

Air cushions are inflatable packaging materials used to fill voids and provide cushioning in shipping boxes. They are lightweight and can be easily inflated on demand using specialized equipment.

Uses

Air cushions are used to fill empty spaces in shipping boxes, preventing items from shifting during transit. They are suitable for a wide range of products, including electronics, cosmetics, and more.

Benefits

- Lightweight: Adds minimal weight to the shipment, reducing shipping costs.

- Space-Efficient: Can be stored flat and inflated as needed.

- Protection: Provides effective cushioning and shock absorption.

8. Padded Mailers

Overview

Padded mailers, also known as bubble mailers or cushioned envelopes, are envelopes lined with bubble wrap or foam for added protection. They are used for shipping smaller, lightweight items that require some cushioning.

Uses

Padded mailers are ideal for shipping books, DVDs, jewelry, cosmetics, and small electronics. They offer a balance of protection and cost-efficiency. Online retailers and small businesses frequently use padded mailers for their ease of use and reliable protection.

Benefits

- Convenience: Easy to use and seal, saving time on packaging.

- Protection: Provides cushioning and protection against minor impacts.

- Cost-Effective: Less expensive than shipping boxes for small items.

9. Drum Containers

Overview

Drum containers are cylindrical packaging solutions made from materials like steel, plastic, or fiber. They are used for shipping liquids, powders, and bulk solids.

Uses

Drums are commonly used in the chemical, pharmaceutical, and food industries. They provide a secure way to transport hazardous materials, food ingredients, and other bulk goods.

Benefits

- Durability: Strong and resistant to punctures and leaks.

- Standardization: Available in standardized sizes for easy handling and transport.

- Versatility: Suitable for a wide range of materials and substances.

10. Crate and Barrel

Overview

Crate and barrel packaging refers to the use of rigid containers, typically made from wood or metal, to protect large or heavy items during shipping. These containers can be customized to fit the product dimensions and provide superior protection.

Uses

This type of packaging is used for shipping large machinery, automotive parts, and other heavy equipment. It is also used for transporting art and antiques that require extra care.

Benefits

- Strength: Offers robust protection for heavy and oversized items.

- Custom Fit: Can be designed to match the specific dimensions and requirements of the product.

- Security: Provides a high level of security against theft and damage.

Choosing the Right Packaging

Selecting the right type of packaging is crucial for ensuring that your goods arrive safely and in perfect condition. Each type of packaging has its own set of advantages and is suited for different types of products and shipping requirements. By understanding the common types of cargo packaging and their benefits, you can make informed decisions that enhance the efficiency and reliability of your shipping process.

Whether you are a business looking to optimize your logistics or an individual shipping a personal item, investing in the right packaging can save you time, money, and potential headaches. As shipping needs continue to evolve, staying informed about the best packaging options will help you navigate the complexities of modern logistics with confidence.

For expert advice and high-quality packaging solutions, trust Cargoline to meet all your shipping needs. Contact Cargoline today to learn more about how we can help you ensure your goods are perfectly packaged and delivered on time.